Published November 17, 2004 at 5:00 a.m.

It's tempting to attribute the success of Jasper Hill Farm cheese to the source: a happy herd of Greensboro grass-eating Ayrshire cattle. But sometimes good old-fashioned luck is what it takes to turn the tide for a struggling Vermont food business.

It worked for Andy and Mateo Kehler. Last spring, New York Times food writer Marian Burros discovered the Northeast Kingdom dairy on a tip from one of the pre-eminent cheese retailers in the country. Rob Kaufelt of Murray's Cheese Shop had recently sampled Jasper Hill's Bayley-Hazen Blue Cheese. He advised Burros to give the thirtysomething brother-farmers a call.

Mateo remembers that day -- June 23, 2004 -- clearly. As the company's cheese maker and salesman, he was having trouble drumming up enough business to make ends meet. From the first batch of cheese, produced in the spring of 2003, he recalls wearing a telephone headset while in production. "I was making regular calls to 80 or 90 clients a week: 'Do you need cheese this week? Do you need cheese next week?'"

Burros' Times piece changed everything. "The phone started ringing at 6:30 a.m. on the day the article came out," remembers Mateo. "After that, we regularly sold out."

Then a piece appeared in The New Yorker magazine, in which the writer used the better part of a paragraph to extol the wonders of Bayley-Hazen Blue: "It was tangy, sweet, creamy, velvet on the tongue, the most delicious blue cheese I'd ever tasted..." The author went on to reference Liz Thorpe, a buyer for Murray's Cheese. She called the Kehlers "the best cheese makers in America." The fortunes of Jasper Hill Farm have been on the rise ever since.

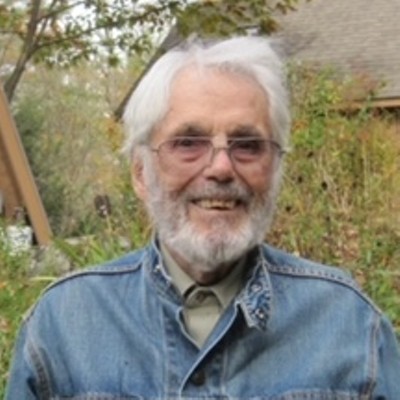

Which is not to say that cheese making is easy work. It is still a long, slow, fastidious process, no matter how many food writers are singing your praises. This small family farm is exactly that: Jasper Hill Farm comprises the Kehler brothers, their wives and Mateo's newborn son. The brothers, who grew up in Colombia and summered at their grandmother's home in Greensboro, milk 28 Ayrshires on their 225-acre hillside dairy farm. They chose that breed, Andy explains, because the small fat globules in the milk make it ideal for cheese making. In time, they hope to expand the herd to 45 milkers.

Andy tends the cows and keeps the books. His wife, Victoria, the keeper of the cheese cellar, handles all the cheese once it's made -- a laborious job of moving and turning and flipping and scraping large wheels of cheese so that they ripen properly.

Mateo, wife Angie and their baby boy live upstairs in the largely unfinished building attached to the old dairy barn where they keep the cows. Still sided with Tyvek, the new building also houses the cheese cellar, the cheese-making room and the office. There is very little wasted space in this operation.

Jasper Hill Farm cheeses come in three varieties: Constant Bliss, Aspenhurst and the aforementioned Bayley-Hazen Blue, named for the old military road that traverses that part of the state. Constant Bliss is a soft, mold-ripened cheese along the lines of Brie or Camembert. The Aspenhurst is correctly described as a Leicester-style cheese that tastes like very mellow cheddar. And that's Leicester, England -- not Vermont.

Mateo says the blue cheese is the most difficult one to make because the conditions have to be perfect. The fluid from three milkings is collected in a round, stainless-steel vat and heated to 34 degrees Celsius. Then the milk is inoculated with the blue mold spores, which begins the process of acidification. Once the mixture has reached the correct pH level, rennet is added to coagulate the milk into a gelatinous mass. After 75 minutes, the cheese maker commences cutting the curd with a harp, the beginning of the painstaking process of expelling the moisture. It will take days and weeks to complete in the cellar's humid atmosphere.

The cylinders of cheese are regularly smoothed with a butter knife to make sure they stay pretty. Too many holes, too much external bluing, too dry, too wet, too ripe -- there's a lot that go wrong with cheese. The Kehlers ended up feeding waste, valued at $60,000, to a neighbor's pigs last year.

"In the beginning," Andy admits, "we shipped a couple of questionable wheels, because we had $150 in the bank and $8000 in bills. But we quickly discovered that you only get one shot, and if you disappoint people, they won't come back. It wasn't worth it to us."

It's not just how much they're selling now, but to whom: The Kehlers are filling orders for such select accounts as Tomales Bay Foods, which distributes to restaurants in the Bay Area and the Napa Valley, and, of course, Murray's Cheese Shop, which supplies the best New York restaurants and the exclusive, California-based French Laundry. They sell to Provisions International out of White River Junction, which distributes to a number of Vermont and New Hampshire co-ops. The brothers are convinced the market for high-quality Vermont cheeses is virtually limitless.

"The FDA just this week put a hold on all soft cheeses from Europe," says Mateo, "so now our clients are calling to find out if they can get more. We're making about 35,000 pounds of cheese a year now; eventually, we hope to be up to 90,000 to 100,000 pounds, but after that you run into issues with quality control. The market is wide open right now. The appetite for cheese is out there."

More By This Author

Speaking of...

-

Q&A: Howard Fisher Delivers Meals on Wheels With a Side of Good Cheer

Dec 20, 2023 -

Video: Howard Fisher Delivers Meals on Wheels

Dec 14, 2023 -

Q&A: Alexis Dexter Rescued 57 Shelter Cats During the July Flood

Sep 13, 2023 -

Video: Two Months After the Flood, Alexis Dexter Rebuilds Kitty Korner Café in Barre and Continues to Rescue Cats

Sep 7, 2023 -

Vermont to Open $20 Million Business Flood Relief Fund

Jul 27, 2023 - More »

Comments

Comments are closed.

From 2014-2020, Seven Days allowed readers to comment on all stories posted on our website. While we've appreciated the suggestions and insights, right now Seven Days is prioritizing our core mission — producing high-quality, responsible local journalism — over moderating online debates between readers.

To criticize, correct or praise our reporting, please send us a letter to the editor or send us a tip. We’ll check it out and report the results.

Online comments may return when we have better tech tools for managing them. Thanks for reading.