Switch to the mobile version of this page.

Vermont's Independent Voice

- News

- Arts+Culture

- Home+Design

- Food

- Cannabis

- Music

- On Screen

- Events

- Jobs

- Obituaries

- Classifieds

- Personals

Browse News

Departments

-

News

Middlebury College President Patton to Step Down…

-

News

Overdose-Prevention Site Bill Advances in the Vermont…

-

Housing Crisis

'We're Leaving': Winooski's Bargain Real Estate Attracted…

- Aggressive Behavior, Increased Drug Use at Burlington's Downtown Library Prompt Calls for Help City 0

- An Act 250 Bill Would Fast-Track Approval of Downtown Housing While Protecting Natural Areas Environment 0

- Through Arts Such as Weaving, Older Vermonters Reflect on Their Lives and Losses This Old State 0

Browse Arts + Culture

View All

local resources

Browse Food + Drink

View All

Browse Cannabis

View All

-

Culture

'Cannasations' Podcaster Kris Brown Aims to 'Humanize'…

-

True 802

A Burlington Cannabis Shop Plans to Host…

-

Business

Judge Tosses Burlington Cannabiz Owner's Lawsuit

-

Health + Fitness

Vermont's Cannabis Nurse Hotline Answers Health Questions…

-

Business

Waterbury Couple Buy Rare Vermont Cannabis License

Browse Music

View All

Browse On Screen

Browse Events

Browse Classifieds

Browse Personals

-

If you're looking for "I Spys," dating or LTRs, this is your scene.

View Profiles

Special Reports

Pubs+More

Battery Innovators Make Vermont a Hub in a Surging Industry

Published October 20, 2021 at 10:00 a.m.

Tucked away in a modest office building in Shelburne, above a childcare center and down the hall from a massage therapist, a group of young engineers is trying to change the world.

Their company, Resonant Link, is developing wireless charging technologies that may someday revolutionize how people power up cars, medical devices and even robots.

In a nondescript conference room, chief technology officer Aaron Stein removed a thin, white doughnut-shaped coil from the center of one of the company's charging units last week and proudly held it aloft.

"This is the magic inside," he said.

The potent technology at the heart of Resonant Link's charging devices was developed at Dartmouth College, the alma mater of Stein and the company's three other founders. When they decided to hone the technology for commercial applications, the group could have set up shop in Boston or Silicon Valley. They instead chose to grow their startup in the fertile Champlain Valley, seeking to tap into the deep pool of talent in the state's fast-growing battery technology industry.

From its roots powering antennas on remote mountaintops and scientific outposts in Antarctica, Vermont's renewable energy industry has emerged as a hub of expertise and innovation in the dynamic energy storage industry.

Today, the state is home to a diverse ecosystem of companies competing and collaborating to meet the surging demand for battery storage systems that are transforming the transportation, renewable energy, health care and consumer products industries.

"The concentration of clean-energy talent and, specifically, battery energy and power conversion talent in Vermont is uncanny," said Adam Knudsen, CEO of South Burlington-based Dynapower.

Companies in the sector are experiencing double-digit growth, receiving an infusion of investment capital and competing for qualified workers. Leading the way are homegrown players such as grid-level storage specialists Northern Reliability and WEG Electric. Both trace their roots to Northern Power Systems, a pioneer in off-grid power solutions founded in Warren in 1974.

Over the years, transplanted businesses have energized the industry with new talent. Dynapower's first CEO, Peter Pollak, moved what had been an automotive-focused firm from Detroit to Vermont in 1989, drawn by the area's quality of life and his connections to the University of Vermont.

More recently, local startups such as Resonant Link and electric aircraft pioneer Beta Technologies have been developing novel battery technologies that place them at the forefront of their emerging fields.

They're all taking advantage of the dramatic drop in lithium-ion battery prices as global manufacturing capacity soars to meet the intense demand from the burgeoning electric vehicle market. Lower prices and ever-improving performance are making it cost-effective to hook up tractor trailer-size battery packs to electric grids, soak up excess power from solar and wind farms, recharge fleets of EVs, and even power all-electric aircraft.

The willingness of utilities such as Green Mountain Power and electricity co-ops to embrace battery technologies to clean up Vermont's power supply is also helping burnish the state's reputation as a leader in the field, said Geoff Robertson, a program director with the Vermont Sustainable Jobs Fund.

"For Vermont to have both the companies working in battery storage and also the utilities that are even willing to consider it — that is unique," Robertson said.

Whether Vermont companies can grow quickly enough to meet demand is a huge unknown and potential stumbling block to further growth. Industries in the state are struggling to recruit employees. Most energy storage companies have multiple job openings for everything from electrical and mechanical engineers to project managers, salespeople and assembly technicians.

That makes the competition for employees intense. Resonant Link just poached Richard Morin from Dynapower to be its new director of business development, for example.

The demand also presents a huge opportunity for young professionals. UVM engineering students with experience building alternative-energy race cars are finding their skills in high demand at firms such as Beta. These young engineers and electricians are eager to work for companies speeding the transition to a carbon-free energy future.

Said Gregg Noble, a vice president at Northern Reliability, "Right now, I've got twentysomethings just soaking up our 50 years of experience."

Here's a look at five of the firms in this dynamic ecosystem.

Northern Reliability: From Antarctica to Suburbia

The loading dock at Northern Reliability's new Waterbury headquarters is packed with stout metal boxes crammed with all manner of electronic gear in various stages of assembly and testing.

The shipping container-size crates house stacks of lithium-ion batteries, as well as the electronic components and controls that allow them to charge or discharge their stash of electrons on demand.

The market for what are effectively huge Tesla Powerwalls is so great that the company has already outgrown the office and manufacturing space it took over from Keurig Green Mountain in January. Its largest battery pack, a mobile unit dubbed NOMAD, is so big that workers had to cut a hole in the loading dock wall to accommodate the 15-foot-tall units.

Northern Reliability was spun off in 2007 from the pioneering Northern Power Systems. By focusing on off-grid power solutions, Northern Power had gained expertise in generating wind and solar renewable energy, as well as storing it for later use.

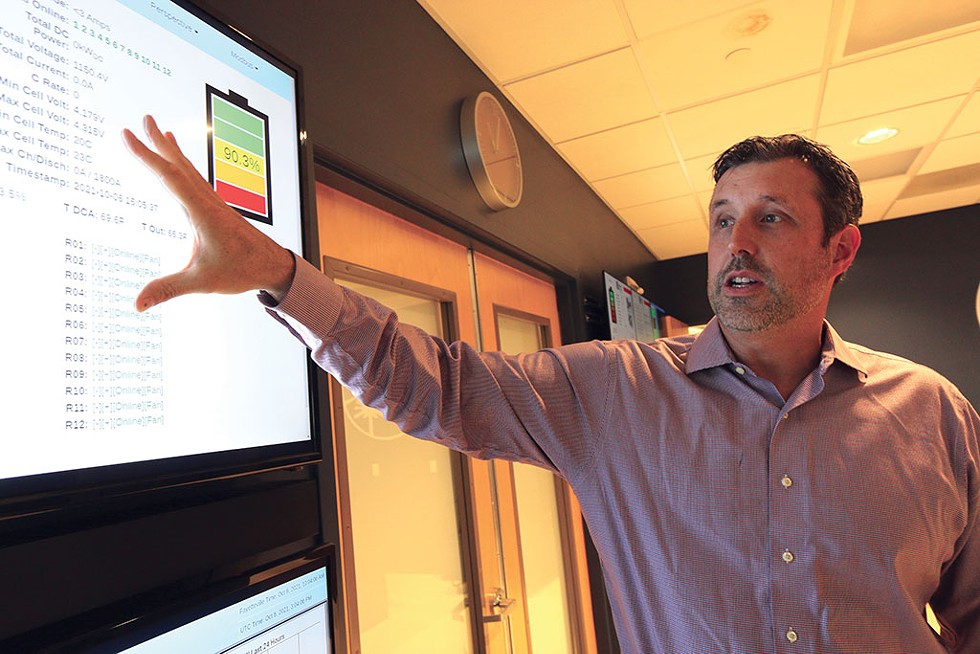

At first, Northern Reliability kept its focus on off-grid technology across every continent, including weather and research stations in Antarctica. But in 2015, the company's new CEO, Jay Bellows, redirected the firm closer to home to help utilities and renewable energy developers use storage to green up power grids. It's a fast-growing sector: Allied Market Research expects the value of the global grid-tied battery storage market to soar from $9 billion last year to $30 billion in 2030.

As it competes with bigger players, Northern Reliability stresses its track record for designing and maintaining durable battery systems in inhospitable climates.

"Anyone can sell you a battery," Noble said. "Putting one at White Sands Missile Range [in New Mexico] on top of a mountain and making sure it works is a completely different story."

Increasingly, the company's batteries are being installed in less extreme landscapes, such as suburban Stapleton, Colo., where many homes are topped with solar panels. The local utility tapped Northern Reliability to design and maintain a network of batteries that would smooth out what amounts to a daily infusion of intermittent power, Noble explained.

But the experience that Northern Reliability engineers gained in harsh environmental conditions — whether Vermont winters or Antarctic extremes — still informs how the team designs and builds its systems, Noble said.

From the thick insulated doors to keep the batteries warm to the air conditioning units to keep them cool — both vital to optimizing battery life and performance — the company's weatherproof enclosures and battle-tested control systems have been keys to its success, he said.

The 25-person company has more than doubled the size of its staff since its pivot in 2015 and is expecting to double again in the next couple years, Noble said.

Much of that growth may come from construction and deployment of its NOMAD mobile batteries, a partnership with battery maker Kore Power. The tractor trailer-size units can effectively replace the diesel-powered generators that provide juice for athletic competitions, concerts and other events with short-term power needs.

Noble acknowledged that assembling such enormous units will likely require more space, but he indicated that the firm is well-positioned to keep growing.

"Stay tuned," he said.

WEG Electric: Barre Complicated

The other branch of Northern Power's former business is now owned by a South American electric motor company that operates in Barre. How that happened is somewhat complicated.

After off-loading much of its storage business in 2007, Northern Power focused on creating large-scale wind turbines. But the publicly traded company struggled financially. It found a buyer for the biz in 2016: the Brazil-based multinational power component firm WEG S.A.

While the wind turbines are no longer built in Barre, its wind power experts are still there, said Chris McKay, director of battery energy storage solutions for WEG Electric, a U.S. subsidiary of the company. The 20 Vermont employees form a sort of crack Skunk Works engineering team focused on WEG's wind turbine projects around the globe, he said.

In 2019, the firm snapped up what remained of Northern Power's energy storage business, which it is now positioning for rapid growth. McKay's side of the operation focuses on designing and selling grid-scale batteries, meaning it competes with Northern Reliability.

WEG also specializes in delivering the whole package of design, permitting, construction and management of the battery units long-term, McKay said.

Large utilities and organizations embarking on expensive, long-term energy storage projects want to partner with stable companies; WEG offers both an agile U.S. team and the backing of a large international corporation, McKay said. WEG has 30,000 employees around the globe and $4 billion in revenue.

Grid batteries are increasingly connected to wind and solar projects; the devices store energy for when the sun sets and the wind stops blowing.

Vermont-based Encore Renewable Energy's new solar setup at Middlebury College is an example. The project will generate 30 percent of the college's power needs, inching it closer to its goal of becoming carbon neutral by 2028. When complete, a battery will be able to soak up 2 megawatts' worth of electricity from 29,000 solar panels during the day and discharge that power when it's needed.

Utilities that purchase power on regional grids can also use such batteries for a cost-cutting advantage known as "peak shaving." They buy electricity when it's cheap, store it and dip into these reserves when prices peak, such as on hot summer evenings when air conditioners across New England are cranking.

The Vermont Electric Coop partnered with WEG in 2019 to create a 2-megawatt battery project in Hinesburg. And earlier this year in Barre, WEG completed an investor-owned 5-megawatt battery, now the state's largest and one that GMP uses to keep power costs down.

Vermont has become a "miniature center of excellence" in the energy storage space due to a unique blend of its strong environmental ethos and independent thinking, McKay said.

"The expertise that is here from years of being involved in these kinds of activities has lined the state up well to lead an industry that is taking off," McKay said.

Dynapower: Keeping the Power Flowing

Dynapower has reinvented itself before, and it's in the process of doing so again.

When the company was based in Detroit, it focused on power converters for the auto industry. After moving to Vermont in the late 1980s, it expanded into power components for industries such as mining, aeronautics and the military, including the systems that power the Patriot missile-defense systems.

The company specializes in the kind of "bidirectional inverters" that allow energy to flow back and forth between renewable energy projects, the grid and storage batteries.

Five years ago, clean energy represented just a fraction of the company's total business. Today, it's half. In three years, CEO Knudsen expects it to be three-quarters.

Striding through the company's cavernous 150,000-square-foot South Burlington facility last week, Knudsen pointed out power conversion systems heading to U.S. Department of Defense installations that he couldn't discuss, as well as others ready for shipping to large-scale solar projects in Massachusetts.

Energy storage is growing so quickly that the Vermont companies in the sector tend to work with one another instead of directly competing, he said.

A 100-kilowatt Northern Power wind turbine has spun outside Dynapower's facility since 2009, and Dynapower converters are integral components in the systems that Northern Reliability builds, Knudsen said. This includes a backup battery system installed at the Statehouse in 2020, which eliminated the need for the historic building's diesel-powered generator.

"The battery energy storage market is so large and has such huge needs that it allows just a ton of opportunity for collaboration between organizations," Knudsen said.

Finding enough workers is a challenge, but it's one the company is meeting in a couple of ways. It partners with contract manufacturing firms, such as Manufacturing Solutions in Morrisville, when jobs get too big to handle in-house, Knudsen said. It also recruits out of state. In the past 12 months, Dynapower has hired more than 30 workers, bringing its staff total to 160. Some designers and salespeople work remotely from North Carolina or California.

"I have given up finding the best people that will move to Vermont to help support our growth," Knudsen said. "We're out there looking for the most talented people, period, and you know what? We don't care where they live."

Beta Technologies: Flying High

click to enlarge

- Kevin McCallum ©️ Seven Days

- Beta Technologies engineers installing the aircraft's batteries

Sean Donovan's job at Beta Technologies isn't as sexy as those of the pilots who get to practice vertical takeoff and landings on its experimental Alia aircraft.

But his work to build better battery packs is just as crucial to getting its all-electric flying machine off the ground.

Donovan's job as a mechanical engineer on the battery team is to maximize the power output of the 20,000 lithium-ion batteries aboard Beta's aircraft, minimize the weight and convince federal regulators that the whole thing won't catch fire in midair.

It's a tall order, and he and the Beta team are going to great lengths to custom-build batteries that will surpass the rigorous safety standards that Federal Aviation Administration officials are likely to require before certifying the aircraft.

Beta will have to prove that the aircraft — in particular the 650 pounds of batteries that account for half its weight — can perform safely in extreme weather and temperature conditions.

"The battery is such a core part of the aircraft, so it has to be bespoke," Donovan said between roars of successive F-35 jets flying over Beta's battery fabrication facility in Williston.

One of the key challenges is to make the battery packs as light as possible. The batteries themselves — mass-produced cells similar to those that give a Tesla electric vehicle its punch — make up 80 percent of the battery pack weight. The remaining 20 percent comes from the wiring, fasteners and housing that keep it all together. That's where Donovan is looking for weight savings that don't compromise safety.

Lithium-ion batteries can overheat. In 2013, custom-built batteries on a Boeing 787 Dreamliner caught fire, grounding the fleet for three months. Boeing and its battery supplier were faulted for not ensuring that overheating cells wouldn't ignite neighboring ones, known as thermal runaway. The company redesigned the battery packs in part by encasing them in steel boxes.

Beta's battery packs are several generations removed from those early efforts, but Donovan nevertheless knows the company is "going to be held to the crazy extremes" in the FAA certification process.

To lighten the battery packs while preserving their safety features, engineers are crafting many of the components in-house. Last week, technicians molded thin strips of plastic that would hold the cells snugly in each battery module. They perform the tedious process themselves to ensure that the plastic sleeves achieve a uniform thickness, thus shedding any unnecessary weight.

"Just adding a gram at the cell-group level is adding a kilogram to the aircraft," Donovan said.

For a company trying to squeeze maximum aircraft range between charges, every ounce matters. Over the summer, Alia flew 205 miles on a single charge, well on its way to achieving a target range of 250 miles using the energy-intensive vertical takeoff and landing mode.

When the aircraft lands at one of the charging pads that Beta wants to deploy across the nation, battery technology would come into play again. The batteries wouldn't be charged off the grid but from battery banks, much like those that Dynapower is selling for EV charging stations.

When the aircraft touches down, it's going to need a lot of energy fast. A battery pack can trickle charge off the grid when not in use, then dump all that power into an aircraft in a matter of minutes — without stressing the grid, he explained.

"It's in the realm of charging five Teslas simultaneously," Donovan said. "It's quite a bit of power."

Resonant Link: Wireless Charging

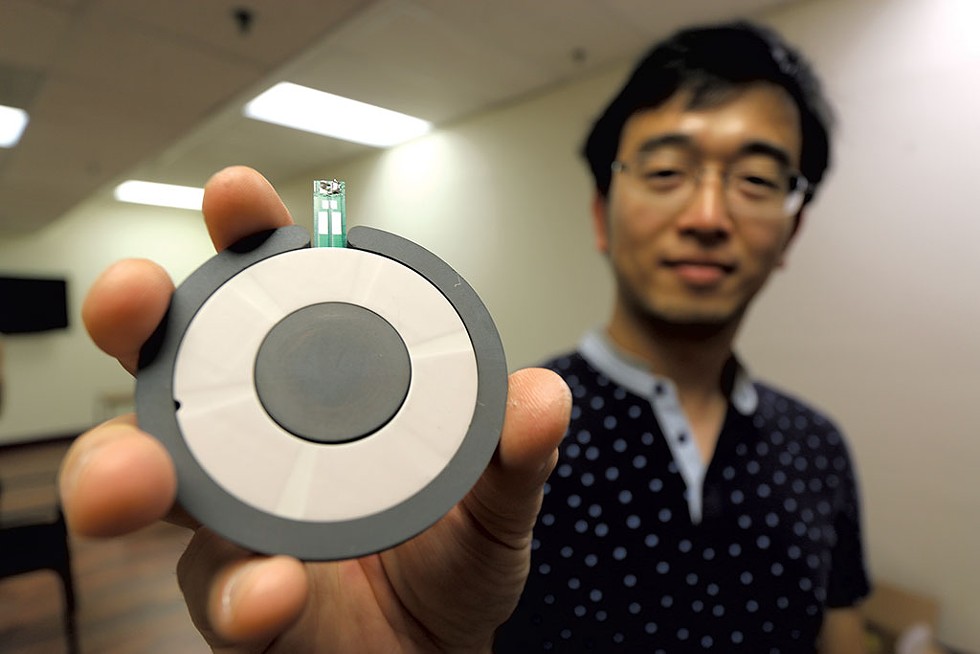

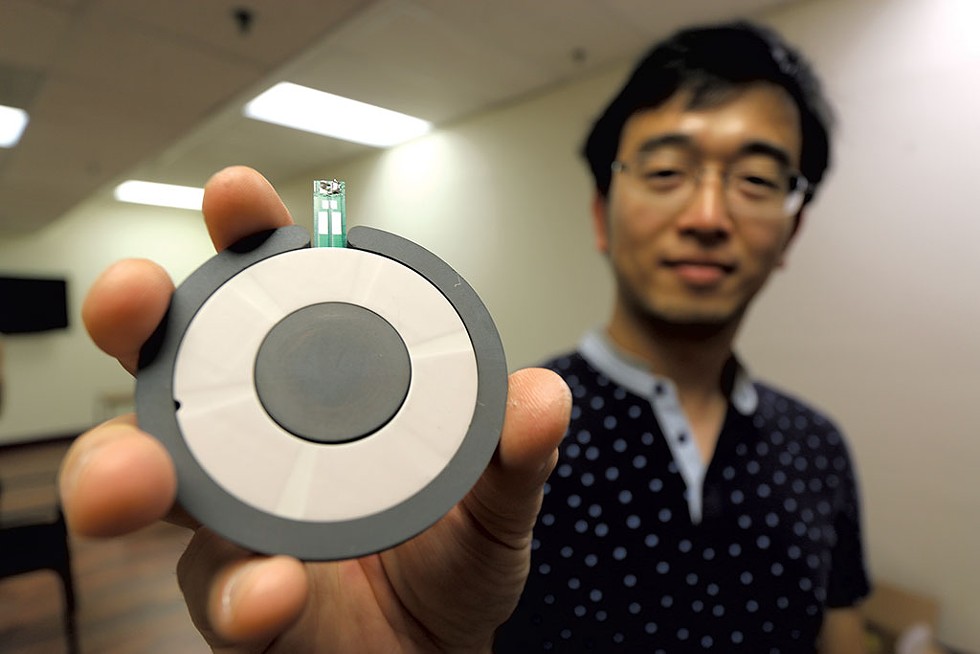

click to enlarge

- Kevin McCallum ©️ Seven Days

- Phyo Aung Kyaw of Resonant Link showing a wireless charging component

Beta Technologies expects to recharge its airplanes with thick power cables for the foreseeable future. But the day is coming, if those Resonant Link engineers in Shelburne have anything to say about it, when electric aircraft and other machines and devices can be charged without power cords.

Cellphone manufacturers have been offering wireless charging for years, but speeds still lag behind wired charging, said Grayson Zulauf, the startup's chief executive officer.

The company's technology delivers the juice at a speed five times greater than conventional wireless methods.

Wireless chargers work by using resonant inductive coupling, in which a magnetic field induces electricity to leap from one coil to another nearby one. The technology is not new — think Nikola Tesla, who first employed it in the 1890s. And it's been incorporated into medical devices in a limited way for decades.

Resonant Link, which was founded in 2017, is working with a more power-dense, efficient coil design that the company's founders invented at Dartmouth in 2013. It's called a multilayer self-resonant structure. In the simplest terms, the coil is more efficient because it uses foil sheets that are 10 times thinner than typical copper wire, Zulauf explained. How those thin sheets are arranged allows the company to cram more power into a smaller package.

Better wireless charging could make pacemaker battery replacements a thing of the past. It could also vastly improve the lives of people who live with medical devices that are now powered by wires that run into their bodies.

The company's target markets also include EVs, consumer electronics and mobile robots used in manufacturing. Zulauf envisions fleets of vehicles that would recharge automatically when parked over charging coils, eliminating the need to plug in. Mobile robots' batteries could be juiced up when they return to a warehouse docking station. Charging coils in loading docks could keep forklifts ready for use.

Last year, the company's staff consisted of its four founders. It now employs 16. Resonant Link has developed relationships with eight medical device manufacturers and has an upcoming pilot program meant to prove its wireless EV promise.

Said Zulauf, "We're lucky and honored to be part of the growing clean-energy cohort that's forming right now in the Burlington area."

Talk with representatives from Beta Technologies, Resonant Link and Dynapower at the Vermont Tech Jam on Saturday, October 23, at Hula in Burlington from 10 a.m. to 1 p.m. and 1:30 to 3:30 p.m. To attend the event, register at techjamvt.com.

The original print version of this article was headlined "Charging Ahead"

Got something to say?

Send a letter to the editor

and we'll publish your feedback in print!

Tags: Tech, Tech Issue, battery power, batteries, Resonant Link, Dynapower, Northern Reliability, WEG Electric, Beta Technologies

About The Author

Kevin McCallum

Bio:

Kevin McCallum is a political reporter at Seven Days, covering the Statehouse and state government. He previously was a reporter at The Press Democrat in Santa Rosa, Calif.

Kevin McCallum is a political reporter at Seven Days, covering the Statehouse and state government. He previously was a reporter at The Press Democrat in Santa Rosa, Calif.

find, follow, fan us: