click to enlarge

- Sally Pollak ©️ Seven Days

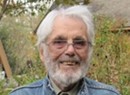

- John Welsh in his workshop

During the pandemic lockdown, when his cobbler shop was closed, John Welsh carried a cruller and a cup of coffee to the storefront he rents in Williston and showed up for work anyway. There were no shoes to repair, but he kept himself busy at Town Cobbler. Welsh used needle, thread, powder dye and rawhide to make tom-tom drums.

"I need a place to go to do this," Welsh said. "This is my place to go."

Welsh, 81, originally opened his business in Shelburne and operated it there for roughly 25 years before moving it to the strip mall in Williston, where he's spent another quarter century. Town Cobbler is a throwback to a simpler time, when young people learned a trade through apprenticeship or family tradition, and folks were more likely to repair an item than to throw it out and buy a replacement.

"The old-timers always got their shoes repaired," Welsh said. "They know the game, and they threw money at it."

Due to health issues that sent Welsh to the hospital in recent months, he does little repair work these days. But he still goes to the shop two or three times a week to "do the bullshit," he said, such as answering the phone, taking orders and managing paperwork.

Town Cobbler employs three cobblers (one is part time), who repair handbags, baseball gloves, belts, backpacks and — mostly — shoes. They fix stitching, craft leather patches, replace heels and rebuild soles.

The shop smells like cement, leather and polish, the aromas commingling to create a workmanlike scent of their own. Pairs of shoes lined up on a rack, heel side out, offer intriguing evidence of the feet that typically fill them. Each fallen arch and wrecked sole is a hands-on problem to be solved with precision and dexterity.

"We'll dress that shoe up so it looks like it did when you bought it," Welsh said.

All of this is familiar and ordinary to Welsh, but it's neither of those things to many people — or in the wider cultural landscape. Welsh gained a new sense of gratification in his shop's work 10 days ago, when he happened on a PBS television show about a multigenerational Italian shoemaking outfit.

"I said, 'Holy shit,'" Welsh recounted of his reaction to the show. "'We're doing what that guy's doing at the factory.'"

His is a dying craft. According to the Shoe Service Institute of America, a trade organization, there are roughly 4,000 cobblers in the country, down from 7,500 in 2000. Over the course of a century, the decline has been steep: In 1928, the nation was home to 120,000 cobblers.

"No one's learning the trade," explained Jim McFarland, 56, a third-generation cobbler in Lakeland, Fla., and the organization's historian and past president.

Welsh expressed the same idea in different words: "If you were born into the cobbler business, you got involved in it," he said. "Today, the kid says, 'I want to be a computer something.'"

Yet, as McFarland noted, "There are 300 million people in the country. There's plenty of shoes to repair."

The 2015 closure of Winooski's Onion River Cobbler made Town Cobbler the sole shoe repair shop in Chittenden County. In Barre, Boisvert's Shoe Repair is a five-generation family business that has occupied its current location since 1950. In addition to repairing shoes, it sells belts, boots, wallets and other leather products.

Welsh grew up in Winooski, where he was kicked out of high school for "being a piece of work," he said. Cobbling was not in his family; his father was an assistant manager at the Grand Union in Burlington.

click to enlarge

- Sally Pollak ©️ Seven Days

- Italian cobbler's hammer

In 1970, Welsh was working as a cop in Shelburne and looking for a hobby. He wasn't interested in fishing, he joked, but he had a hunch that cobbler work would interest him. One Friday evening after his police shift, he walked into DePaul's Shoe Service in Winooski (now gone) and asked proprietor John DePaul to teach him the trade.

He told DePaul he didn't want any money, just to learn shoe repair. When the "hobby" became a more serious commitment, the two agreed that if Welsh ever went into business on his own, DePaul would buy him his first set of supplies, such as rivets, needles and thread.

"So I go in after work, hang my gun up in the corner, and I did shoes," Welsh recalled. "I got pretty good at it."

The cop's interest in shoe repair grew. He learned about the products, got to know the salesmen and became skilled at running the sewing machines and the buffer. He liked seeing what he had accomplished at the end of the day. When he heard that a warehouse of used shoe repair machinery was for sale in Boston, Welsh borrowed a flat-bed truck, "got a few guys who owed me from my police" work and drove to the city to purchase the machines.

He put the equipment in his Shelburne basement and started doing repair work — fixing the straps on women's handbags and mending broken heels.

"I put all the money back into the repair business," he said. "All the money went back into the game."

In the mid-'70s, while still a sergeant on the force, Welsh opened Town Cobbler in a barn on Shelburne Road. He trained high school students in shoe repair and leather work through a vo-tech program at Champlain Valley Union High School.

Along with doing repair work, they made gun holsters. At one point, Welsh discovered that the kids were selling pot out of his shop.

"I leaned on them pretty big-time, and they stopped," the ex-cop said. "They were kids that didn't have a chance."

In the early 1990s, when highway work on Shelburne Road restricted access to Town Cobbler, Welsh started looking for a new location. He eventually moved his business to Williston.

Jared Place has worked at Town Cobbler for the past 11 years. A graduate of Winooski High School, he specializes in leather work that often involves sewing and patching, he said.

"You have to get to know the tools and how to repair things, but every job is different," Place, 46, said. "It's a lot of thinking on your feet, a lot of improvising and a lot of adapting."

Many mass-manufactured shoes are made to be thrown out, Place said. But there are brands producing quality footwear worthy of repair, such as Birkenstock, Frye, Red Wing Shoes and Thursday Boot. He'll offer a straightforward appraisal of when and if a shoe is ready for repair.

Last week, Place advised one would-be customer that a crack in a leather boot could have been forestalled (with oiling) but could no longer be fixed. He also punched a hole in a customer's leather belt free of charge. "We just ask for a donation to the food shelf," he said.

Welsh said he has no plans to retire. The shop gives him a place to go, people to talk with and side projects to work on. In addition to the drums, he crafts reproductions of other Native artifacts, such as pipes and bear-tooth necklaces. He displays and sells the objects at Town Cobbler.

Welsh's two children died as young adults. His daughter, Celeste, died in 2008 as a result of traumatic brain injuries she suffered in a horrific car accident 15 years earlier, Welsh said.

"The doctors told us she was going to be in turmoil all her life if she lived," he said. "They forgot to tell us we were going to be in turmoil all our lives."

His son, David, who was learning to be a cobbler, died of a drug overdose in 2014 at age 32, Welsh said. His ex-wife also predeceased him.

"I live alone," he said. "I got to have a place to go every day."

Business is down by about 45 percent since the pandemic, Welsh said. Still, he's trying to hang on in the strip mall.

We live in a disposable society, both Williston cobblers said. Consumers are more inclined to purchase items in quantity than for quality, Place observed.

With the supply of cobblers dwindling, people need to realize that shoe and handbag repair won't always be available to them, Welsh said. His succinct message to potential customers: "Use it or lose it."

![Onion River Cobbler [SIV252]](https://media1.sevendaysvt.com/sevendaysvt/imager/onion-river-cobbler-252/u/square/2291802/episode252.jpg)