Published April 22, 2008 at 5:39 p.m.

Some middle-aged dudes might fantasize about rock-star camp. Others will pay a mint to don big-league pinstripes and run around the field. Me, I just wanted to dismember an animal. At times during my decadently carnivorous years, enjoying everything from alligator to yak, I have wondered, "Could I cut it as a butcher?" So I decided to ask one for a tutorial. But, given the proliferation of non-service supermarket meat counters, I wondered if the eager-to-please meat cutters of my childhood even existed anymore.

They do, but their numbers appear to be declining. According to the Vermont Agency of Agriculture, 832 retail outlets still sell meat in the state, but no statistics indicate how many of these are independent butcher shops. In the Champlain Valley Yellow Pages, only five retail meat businesses are listed, a few of them old-fashioned country stores.

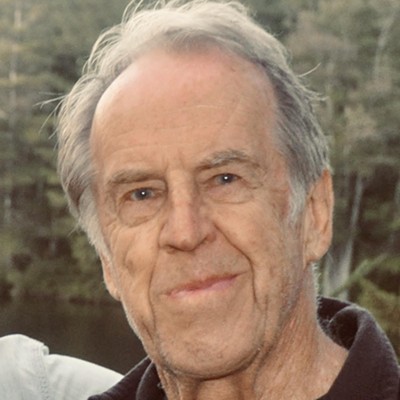

Cole Ward is doing his part to change that. The 57-year-old is the butcher at the Sweet Clover Market in Essex. After 43 years in the business, he's looking to pass on his trade to the next generation. "Training has not kept up, like plumbers and electricians have," Ward laments. "What we need in this state is more quality, qualified butchers. I would like to see more training of people in the lost art of meat cutting."

Though I'm not exactly what he's looking for in a successor, Ward generously agrees to let me intern for a week at his butcher block and write about it. Perhaps he imagines that my article will help spread the word about the need for young butchers.

Day one. I make my way to the "backstage" kitchen area of the local natural food shop. Ward's bulletin board is plastered with orders for special cuts and game meats. The market's employees drift in and out, getting supplies from the refrigerator or just stopping at the coffee maker. Ward, who is dressed casually in jeans and a surprisingly clean apron, looks far younger than his years. His speech has a fast-talking, old-time-show-biz quality, betraying little of his St. Albans roots.

Though I'm eager to get elbow-deep in offal, we start more modestly. Before I can cut meat, I need a lesson in the basics. Ward shows me how palatable cuts for retail consumption are made from the larger, "primal" cuts. This is where most butchers begin these days - opening up vacuum-packed ribs and loins before cutting them into steaks.

I'm surprised to learn that the names for different cuts of meat are not standardized. For us Northeasterners, when you split a blade steak lengthwise (that's the animal's shoulder, and the source of chuck steak) and discard the gristle that runs through it, the ultra-tender result is a "flatiron." In Texas, the same steak is known as a "full cut," and on the West Coast, it's a "triangle cut." The common factor: It must be cut horizontally. A vertical slice will leave the steak tough with a band of gristle through the center - as it is often found in supermarkets.

Ward also shows me how to stock the butcher case. While he's cutting meat, keeping the case supplied, attending to customers, and marinating chicken breasts and kabobs, he also takes phone calls from prospective customers. "The question that I get the most is, 'Were the animals happy?'" Ward says with a mischievous grin. He always points out that nearly all his meat is locally farmed, including Boyden beef from Cambridge and Adams Farm chicken and turkey from Wilmington.

I have to wait until the second day for my Lord of the Flies moment. When it arrives, I don a bloodstained apron. As we wait for a pig to be delivered from North Hollow Farm in Rochester, Ward prepares a specially ordered lamb crown roast. With incredible dexterity, he threads what looks like a giant sewing-machine needle with twine and stitches together two frenched racks of ribs - meaning, all fat and cartilage have been removed from the bones, making lollipop-like holders that Ward dresses in what are known as "lamb panties." Next, he grinds his trimmings and balls them up in the center of the wreath-shaped roast. The result resembles the monkey heads with visible brains served in Indiana Jones and the Temple of Doom, but with a forest of parsley sprigs and ribbon-thin carrots planted around the exterior.

Then our little piggy comes to market. Ward heaves what could be a Damien Hirst sculpture onto his work table. To my vast disappointment, the pig's head and most of the organs have been removed already - though Ward promises me a head at a later date. He quickly detaches the remaining kidney and glands and tosses them into his compost bucket. A fan of sweetbreads, veal cheeks and the like, I ask Ward why he does not use the "fifth quarter," as these innards are called. "I worked in a slaughterhouse back in the early '70s," he explains, "and I am a firm believer that most diseases originate in the organs. I worked in supermarkets where I found big tumors in the liver and just sliced around it," he adds. "I don't want to eat a liver that had a tumor in it." OK, then.

Ward lets me remove the "leaf lard" that coats much of the pig's abdominal cavity. With one hard pull, I proudly detach it, then reserve it in a bucket. Treasured for tasting sweeter than lard from other parts of the animal's body, the leaf lard will later be rendered and used for making pastry dough. Next we break the pig's shoulder, which produces both the "picnic shoulder" - the cut generally used in pulled pork - and the pork butt. Using a large, rectangular bone saw, I get to saw off the shanks, which have been pre-ordered by a Sweet Clover customer.

Then, on to the belly. This fatty cut, very much in vogue these days, is a specialty at the award-winning Hen of the Wood restaurant in Waterbury. Ward reminisces about a common meal he had growing up on an old Vermont farm: pork belly with scorched gravy and potatoes, and a side of Johnny cakes. To illustrate, he deftly seasons some slices of the belly with salt and pepper and throws them in a pan on the stove next to the butcher block. Ward takes a smoke break and leaves the belly to fry. When he returns, we sample his work. It is nothing less than a fat orgasm. So bad, yet so good. Ward explains that bacon is merely thin slices of smoked pork belly.

After this little respite, we proceed to demolish the pig's anatomy, bit by bit. Connective tissue and large chunks of fat go into the compost, but salvageable trimmings are reserved for sausage, which Ward says we will make later. Lazy trimming, he cautions, can lose a butcher several dollars a day. When he was managing a shop in Los Angeles in the late 1970s, Ward says, his boss had a motto: "If it's red, it's mine. I paid for it, I want it."

Speaking of red: Because our pig was alive so very recently, it did not have time to bleed out properly. So Ward and I must pick through and dispose of numerous clots, some the size of golf balls. The faint of heart, or queasy of stomach, should not try this alone.

Ward, of course, is unfazed, and proceeds to regale me with more fond remembrances of his L.A. years. "I used to do all the meat props for CBS studios; I used to do displays for Taco Bell television commercials," he says. His customers included such stars as Lucille Ball and Raymond Burr. Because of their busy lifestyles, Ward says, he had to provide more oven-ready food than he does in Vermont today. He discloses that Burr - a.k.a. TV's Perry Mason - "ate a lot of pot roast."

I help cut spareribs from the pig and take them home for a dinner of Memphis-style ribs.

The next day, Ward and I reconvene to break down a full side of beef, which, at a cost of more than $1000, will be split by two local families. A hook is hung from the ceiling of Sweet Clover's tiny kitchen. Dustin Hendy, a junior culinary student at the Essex Technical Center, joins us. He's been working with Ward for several weeks for school credit. The two have an easy, joking rapport. "He's a fun person to hang around, but we get things done," Hendy assures me.

Ward is currently seeking an apprentice for Sweet Clover's meat department, but it hasn't been easy. "We've had some trouble finding someone," he says with a shake of his head. "There's been a few people that came forward. What we want from an apprentice here is to know where it comes from in the animal, because if you know where it comes from, you know why it's tender. It's surgery, to some degree."

Ward thinks Hendy shows promise. "He has a natural talent for this," says the butcher. "What we really want is an apprentice with no bad habits to break." As Ward ties a shoulder roast in a butcher's knot (the Boy Scout-style standard used to keep meat in an attractive, rounded shape when cooking), Hendy says with visible pride, "I'm good at that. It usually takes a month. I learned it in 10 minutes."

Indeed, it takes a rare person to become a butcher today, but Hendy says his early interest was sparked when he watched a family friend cutting meat at Gaudette's Slaughterhouse in Georgia. "My grandpa would take me to the slaughterhouse to go see the hanging meat," he recalls. "It didn't bother me. Some kids, it would. I kinda liked it."

Ward teaches the two of us how to take apart the front end of the cow, called the forequarter, on the table, but the hindquarter is so large it must be dismantled while hanging. This is a chore - the meat-cutting equivalent of painting the Sistine Chapel. Perhaps it helps explain why the art of butchering is on the wane.

On Sunday, Ward and I use up the rest of our pig, which has been stored in Sweet Clover's modest walk-in refrigeration unit. Ward prides himself on his innumerable sausage recipes - everything from lamb-and-mint to British bangers, and even chorizo. Today we make apricot sausages with Chinese five-spice powder, a process that starts by grinding the marinated meat in a huge machine, which looks every bit as cool as the one in Pink Floyd's The Wall.

We add the spices and dried apricots, then prepare the dried, salted-pork casings, which must be flushed before use. This procedure looks very much like filling a fire hose, except for the casing's visible membranes. Next, Ward threads the casing onto a nozzle attached to the grinder. Little by little, the sausage is fed into its condom, and Ward lets me pinch and twist the long tubes into individual links. The results of our labor: sausages somewhere between breakfast- and dinner-size, sweet with a strong note of cinnamon. Gorgeous.

At the end of my week as an apprentice butcher, I am tired and sore. I've had a blast, but concluded that I'm physically better suited to sitting at my computer and writing. Later this spring, I'll return to Sweet Clover Market to help Ward with the nine-hour process of making hot dogs. Until then, I'll let someone else cut up my meat.

More By This Author

Speaking of...

-

Sweet Clover Market in Essex to Close

Feb 13, 2024 -

Q&A: Howard Fisher Delivers Meals on Wheels With a Side of Good Cheer

Dec 20, 2023 -

Video: Howard Fisher Delivers Meals on Wheels

Dec 14, 2023 -

Last Quarter: Fall 2023 Vermont Housing News

Oct 3, 2023 -

Outdoor Gear Exchange to Downsize in Burlington, Open New Essex Storefront

Sep 28, 2023 - More »

Comments

Comments are closed.

From 2014-2020, Seven Days allowed readers to comment on all stories posted on our website. While we've appreciated the suggestions and insights, right now Seven Days is prioritizing our core mission — producing high-quality, responsible local journalism — over moderating online debates between readers.

To criticize, correct or praise our reporting, please send us a letter to the editor or send us a tip. We’ll check it out and report the results.

Online comments may return when we have better tech tools for managing them. Thanks for reading.